We all know the basics of how metal casting works, a metal is heated up to melting point and the resulting liquid metal is poured into a mold. When the metal sets, it assumes the shape of the mold. It’s a straightforward way to reliably replicate a metal item many times over, and the basics are the same whether the metal is a low-temperature alloy in a silicone mould or a crucible of molten steel poured into a sand mould.

What we all understood as casting in our conversation was sand casting. Sand is packed around a pattern of the piece to be cast, and then the pattern is removed leaving a cavity in its shape which becomes the mould. There are refinements to this process and the mould is frequently formed in two halves, but it’s something that’s even practical to do in a hackerspace level setting. Zinc Die Casting Parts

A refinement of sand casting is so-called lost-wax casting, in which a hollow wax model of the piece to be cast is packed around with sand, and when the metal is poured onto the top of it the wax melts and the wax is melted out before pouring the metal in to take its place. A variation on this appears here from time to time, so-called lost-PLA casting, where the wax model is replaced with a PLA 3D print.

Where our confusion crept in was with die casting. We could recognise a die-cast piece, but just what is die-casting, and how is a die-casting made? The answer there lies in mass-production, because a snag with sand casting is that a sand mould can be labour intensive to produce. Much better to come up with a quick-turnaround process that re-uses the same mould over and over, and save all that time!

Enter the die-casting, to metalwork what injection moulding is to polymers. The die is a mould made out of metal, usually with liquid cooling, and the casting is done not by pouring but by forcing the molten metal into the mould under pressure. The whole process becomes much quicker, meaning that it can become a piece of process machinery spitting out castings rather than a labour-intensive individual task. The metals used for die-casting are the lower temperature ones such as aluminium, zinc, and their alloys, but you will find die-castings in all conceivable places.

It’s obvious that Hackaday editors are not experienced foundrymen even if some of us grew up around metalwork, but we know that among our readers lie genuine experts in all sorts of fields. If that’s you and you operate a die-casting machine, please take a moment to tell us about it, we really would like to know more!

Header: Constantin Meunier, Public domain.

Just a note about lost wax: NEVER try to melt the wax pattern out with the molten metal. The wax is `burned out’ prior to pouring.

Also, never forget lost foam as an option.

And here I was wondering how you get the wax residue out of the metal parts…

Oh, it comes out on its own just fine, along with an absolute fountain of molten metal. My multiple attempts at metal-burn-out PLA casting have produced the same result: aluminum volcano and nothing even like a decent casting when it’s done spraying.

The ones I’ve seen with PLA use either vase mode or a standard print with a single perimeter and no higher than 10% infill. Needs a lot of venting and the sand needs to be a mix that will allow plastic vapor to escape into it. This guy coated his PLA prints with joint compound then buried them in sand. https://www.youtube.com/watch?v=YKeImuJpxow There are several more videos there to be found with a search for lost pla metal casting

Ahhh, very good to know! Saved me from a possible Darwin Award, at least for now.

Apologies, I guess I need to admit I’m a blacksmith’s kid not a foundryman’s.

Lost-[wax/foam/PLA] a.k.a. investment casting

Has anyone ever tried 3D printing a sand mould? Could it be done? How? What would be the obstacles? Inquiring minds want to know!

There are 3d printers that work with sand for this purpose. But it still is time-consuming

Myfordboy [Youtube] has been doing that for years, and showing how-to’s on his channel.

I’ve never seen him 3d print sand moulds, but I know he uses 3d printed parts to make his patterns.

I’ve 3D printed positives for a sand mold – spray with lacquer for a smooth finish. Given the physical properties of casting sand, if you wanted to ‘print’ a sand mold I think milling it with a CNC + vacuum attachment would be your best bet. Pack the sand into a box, put it on your mill and carve the shape.

Related but not identical: I’ve 3d printed a core box, filled with sand/sodium silicate, and then cured, for a sand core for water passages in a casting. It’s convenient that you can use the 3d print that’ll be the lost-PLA master, also as the core box since that’s where the core will be anyway. (Some complexities with the core print ends, where they register into what would be sand in a sand casting, although I’m doing investment casting, but that’s something you can solve with double stick tape and bits you’ve adhered onto the side of the mold.)

Yes, this can be done.

You 3d-print sodium silicate solution on regular sand. The action of CO2 on the sodium silicate causes it to harden into silicon dioxide, which causes the sand grains to stick together.

An actual machine has a bed of sand, goes over the sand with something resembling an ink-jet printer head that deposits the liquid, then a wiper comes across leaving a thin layer of sand, and the process repeats. When everything is done, you remove the hardened mold from the loose sand, shake out any un-hardened sand, and pour directly.

You can blow C02 up through the bottom of the sand to promote the conversion, or just let it sit. The CO2 in the atmosphere is enough to convert water glass into hard silicate.

Any love for Zamak? That alloy so popular for die cast/injection molding? Can’t weld it, can’t solder it, can barely braze it, can hardly glue it, looks like junk after a single season outdoors. But it sure is popular for cheap injection-molded parts, like all those little kids toys from way back when. Takes powder-coat well too.

Just looking around the kitchen – the stand mixer body is made from it, as are measuring cups, flour scoop, garlic press, olive pitter, espresso machine, and probably more. Vespa parts too. Do Italians love the stuff or something?

That’s really interesting. I hadn’t heard of ZaMaK before. Very interesting that it has a melting point just above where the high temperature plastics typically melt, but well below aluminum.

As usual, there are different compositions that are optimized for different uses. Zamak 4 is said to be developed “for the Asian markets”, i.e. cheap reproduction because the molds last longer. The tradeoff is significantly lower impact strength.

That’s a big problem, because a lot of furniture nuts and fixings etc. are made out of zamak, and when they’re made out of the wrong zamak they just snap, often just as you’re assembling the thing.

Zamak, also known as pot metal(because you can melt it in a pot) is a zinc/aluminum alloy(90+% z, 4% AL, and other stuff) is easy to cast , takes detail well, is hard, but brittle and subject to corrosion. The main drawback from a hobbyist stand point is that the melting point is so low that it is hard to avoid over heating it and this causes zinc to vaporize. Inhaling zinc vapor leads to metal poisoning, which has lots of quirky and uncomfortable symptoms, including death. I recommend Aluminum, the temps involved are higher but well within the hackerspace range and the results can be machined for final finish.

It’s not particularly brittle if you have the right amounts of other stuff in it. There’s about 0.2% – 1% of copper, magnesium, iron, tin, etc. in the composition which makes the impact resistance about 40-60 Joules. If you only have trace amounts, the impact resistance can drop to around 7 Joules.

To put things in perspective, 7 Joules is the energy of a toy BB gun. 50 Joules is the energy of dropping a 5 kg kettlebell from 1 meters.

Zamak seems useful. I like all the variations available, I even read about graphite-reinforced Zamak metal-matrix composites. DIY-able?

I want to cast a few things like tabletop minis, metal Beyblades parts, or weights for 3D prints. I’m thinking that I’ll challenge myself with a gauntlet, starting with low temp and easy-to-cast metals, then getting bigger and higher temp.

Pewter is another good option for models.

Growing up in the 90s we called it chinese-ium. Usually because “made in china” was stamped or cast into the part somewhere and it usually failed with a little hard use.

I had no idea it had an official name let alone varying grades.

Lost-wax and lost-PLA require the wax/PLA to be melted out prior to casting.

Another mechanism to consider is ceramic shell casting. Where a PLA or wax model is coated many times in a ceramic slurry, which hardens into ceramic shell. The wax/PLA is melted out and the shell is used to cast.

Also, literal metal injection molding does exist and is quite a mature process. It uses MIM powders held together with a binder, forced into a mold. Only the binder melts in this process. The part is then ejected and sent to a sintering furnace. MIM powders can also be used in a 3D printing type process where binder is selectively applied to a bed of MIM powder in layers, then sent for sintering.

MIM powders range from low alloy steels to stainless, tool steels and even tungsten carbide.

Aluminum is really not that difficult, and propane can be surprisingly efficient with proper burner and foundry design. I’ve spent the last 5 summers going from KOR sand and perlite refractories and reil burners to a completely custom design based on hard firebricks, ITC-1000, and a custom 3-burner setup that self-regulates airflow based solely on their natural venturi effect. Pro-tip – use .023 or .025 mig tips as your orifice and 1/2 inch copper tubing as the body – .030 and .035 require a stupid amount of gas flow to get the same velocity, same with larger pipe diameters.

Nothing quite as satisfying as showing someone a cast custom part – then telling them it’s made primarily of beer cans.

From memory die casting moulds were very similar to polymer moulds, sprue runner and gate had larger cross section, aluminum parts tended to have thicker section than high ratio zinc, parts were ejected in the same way. mould faces were sprayed with a graphite solution to aid this, moulding machines looked similar but die casting machines had piston in barrel whereas polymer machines had screw in barrel. die casting shop was a lot dirtier than polymer shop due to the graphite. cold flow tooling endured very high tonnage, powder metallurgy tooling very close tolerances.

Some older injection moulding machines had piston as well.

True,I think the old Edgewick’s had pistons, in fact the screw has variable pitch, as the screw rotates melting and pushing the polymer forwards the screw retracts, the retraction length equals the amount of shot, then the screw acts as a piston pushing the shot into the mould.

There is one more variant of ‘metal injection moulding’, where what is injected is not a molten metal, but a metal-dense mix of metal powder and a fluid or fluidised binder. After the part is injection moulded, this ‘green’ part is then sintered in a high temperature oven to remove the binder and bond the metal particles together. This allows injection moulding of high temperature metals, though requires the mould to take into account the shrinkage between green and final part. This injection moulded variant is what you will be dealing with when the colloquial term ‘metal injection moulded’ is used in reference to a part, rather than die-casting.

Saturn car company used to sand cast their aluminum engine blocks. They molded expanding styrofoam in the shape of an engine block, then coated it with ceramic slurry. After double coating and drying, it was packed in sand and the molten aluminum was poured into one sprue hole. Flames poured out of the other sprue holes as the styrofoam burned away. After cooling, the casting was removed from the sand, the ceramic shell was knocked off and it was finish machined. One really neat thing was that the process kept such detail that you could see the styrofoam texture (just like a styrofoam cup) on the un-machined surfaces of the engine block. Really neat to watch!

I had noticed that styrofoam texture on the block of my old Saturn, and figured that it was probably from the positive mold. That’s really interesting!

Please be kind and respectful to help make the comments section excellent. (Comment Policy)

This site uses Akismet to reduce spam. Learn how your comment data is processed.

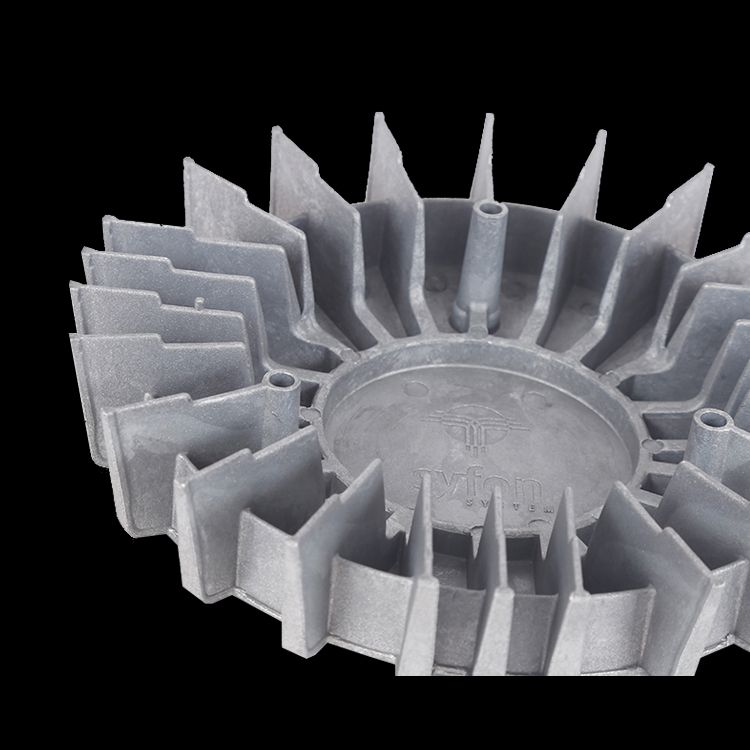

Water Pump Impeller Housing By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more